Mouse Time-Controlled Feeding Cage

- Cheuk Chan

- Dec 3, 2015

- 4 min read

Mouse Time-Controlled Feeding Cage was my senior design project in UCSD. It was sponsored by UCSD School of Medicine. Through this project, I had a chance to work with other specialists to get this project done. It brought me a very valuable experience before working with other engineers or experts in the real work place.

The purpose of this project was to design an automated mouse feeder that can cut off the supply of food to the mice. There have been recent scientific studies that have shown that the time one eats can affect one’s health just as much as the quality of what one eats. For instance, it is well known that regularly eating at night leads to insulin resistance and can cause obesity. This is most likely due to disturbances in the normal circadian rhythm. However, this phenomenon is not fully understood and more scientific research is needed. The sponsor of this project, Dr. Nicholas Webster, performs time-restricted feeding experiments on mice. He has shown that limiting access to food for anywhere between 4 and 16 hours over a period of one to four months leads to weight loss and improved health in the mice. Now he wants to expand his experiments to examine the effects of dietary restrictions on breast cancer growth. In the past, the food supply was manually adjusted by a steady stream of undergraduates working in the lab. This required a lot of person-hours and was somewhat impractical for long-term studies. The goal of this project was to create a relatively inexpensive automated feeder. It was important to have a simple user-interface that could program 8 cages at once.

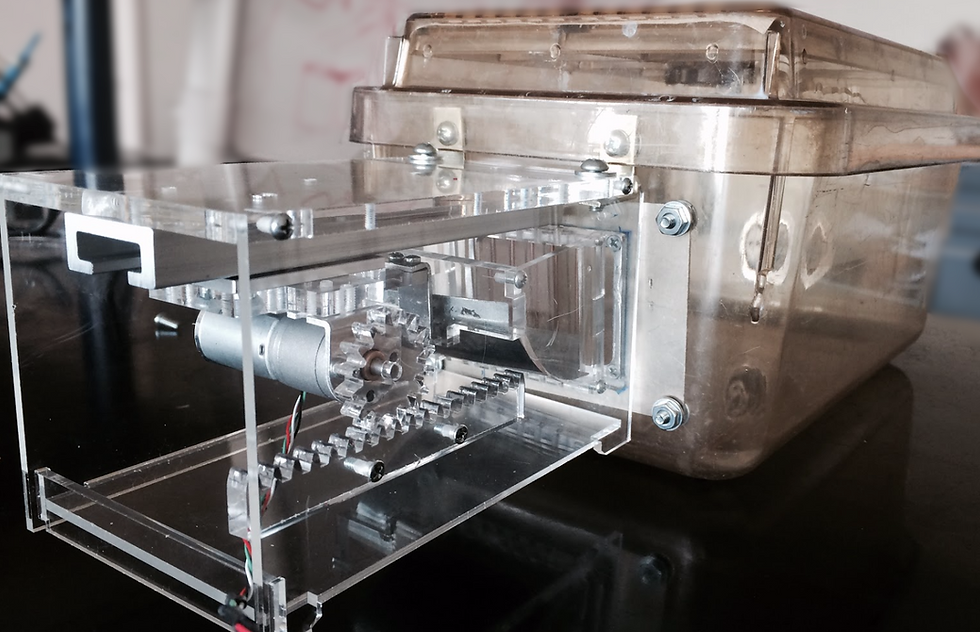

The final design of this project was a feeder hanging on the side of the mouse cage. In the feeder, there were a food hopper, load cell, slider, printed circuit board (PCB) and motor. The feeder was controlled by a data acquisition (DAQ) made by National Instruments (NI). The principal of this feeder was that a user-friendly program was created by LabVIEW which is the designated programming software for NI product and the user could set the desired feeding time and the cut-off time in the program in order to reach the research needs. When the feeding time, the computer sent the signal to the DAQ which connected to the PCB in each feeder and controlled the motor to drive the food hopper towards the cage. After feeding time, the computer would also sent the signal to the DAQ to control the motor to drive the food hopper back in order to cut off the food supply. At the same time, the load cell connected to the food hopper would measure the weight of the hopper and the user would know how much the mice had eaten during the feeding time.

The way the teams were formed was that every student ranked the projects depending on his or her interest, so all the team members of every team should have had high level of interest of the project. Our team was in the same situation. All of the teammates were passionate and hardworking. However, we faced a lot of problems during this project. Since we were all passionate about this project, each of us had different idea and each of us insisted on his own ideas. Each of us had different design to reach the goal of the project and we could not finalize the design after the first two weeks. In order to choose the right design, each of us listed out all the pros and cons about his own design and we discussed together. After the meeting, we came up with a design which consisted of different strong points from each of our designs and it turned out to be a good design for this project. When we started working, we found that our schedule did not fit to each other. Every time I went to our work station, I saw the design changed and I needed to study what had been changed every single time because we did not assign our job clearly and everyone just worked on the things he thought it had been good for the project. It was not the way to have a success in this project and it was only wasting time but not progressing. Therefore, every week we had a meeting together in the beginning of the week to discuss what the tasks needed to be completed in that week and assign everyone’s duty in that week. Eventually, it worked pretty well that we took up our own responsibility and asked for help if anyone had problem. We also left some note about what had been done every time and if there was any help needed. For this process, I learned that when working in a team, communication is the most important element which trust and communication are built on.

On the other hand, since this project crossed over the areas of medical and electrical fields, we needed to get advices from the experts and specialists in these fields. It was very interesting to hear what their opinions were on our design in their professional aspect. I realized that was exactly what the real engineering world is. Behind every product or project, there are a lot of different people from different professions working together. The design of a successful product is finalized after many changes and considerations have been made by these professionals. Therefore, this project brought me some ideas about the work place after I graduate and experience when communicating with other professionals.

This project needed a lot of machining and fabrications in the machine shop so I had many chances to operate some advanced machine tools. Though this project, I became more proficient with these tools and used them to customize and make my own parts and components precisely. These hands-on experiences motivated me to study how products are made by these tools and made me more attentive in manufacturing. Having my own car or aircraft design which could be seen on the street or on the sky has been my dream, so this project had made me more confident to achieve my future goal to be working in Industrial Manufacturing field.

Comments